Biohealth manufacturing involves the development and production of biological products, including biopharmaceuticals, vaccines, and cell-based therapies. This field utilizes living systems, such as cells or proteins, to create treatments targeting complex health conditions. Unlike traditional manufacturing, biohealth manufacturing requires precision to ensure the integrity and efficacy of biologic products.

The significance of biohealth manufacturing is evident in its contributions to biopharma and biotechnology manufacturing. For instance, cell-based vaccines, produced through biohealth processes, have played a critical role in combating global health challenges. A notable example is the development of Flucelvax, the first mammalian cell-based influenza vaccine approved in the United States. Produced by Novartis, Flucelvax utilizes Madin-Darby canine kidney cells and targets multiple influenza subtypes, offering an alternative to traditional egg-based vaccines.

As the demand for innovative biologics grows, biohealth manufacturing continues to be essential in biotechnology manufacturing. Its evolution drives the biopharma sector forward, delivering therapies that improve patient outcomes and support precision medicine approaches.

Integrating AI in biomanufacturing redefines how biohealth manufacturing operates, addressing challenges like process variability and scalability. With its ability to analyze large datasets and predict outcomes, biohealth AI is improving efficiency, accuracy, and consistency.

AI tools can identify optimal conditions for growing cell cultures in biopharmaceutical production, minimizing errors and reducing waste. This level of process optimization is critical in a field where even minor deviations can impact product quality. For example, AI has been utilized to predict protein structures, aiding in developing more effective biologics.

AI’s role in biomedical research has also been transformative. Machine learning models analyze data from clinical trials and genomic studies to identify promising candidates for biologics, accelerating their transition from research to manufacturing. Moreover, AI aids in scaling production—a historically challenging aspect of biomanufacturing. By simulating and modeling various production scenarios, AI allows manufacturers to transition from lab-scale to commercial-scale operations more efficiently while maintaining the integrity of sensitive biologics.

AI in biomanufacturing is meeting current industry demands and paving the way for future innovations through its ability to enhance precision, predict outcomes, and support scalability. The fusion of biohealth processes and AI technology is driving progress across the healthcare landscape, setting new benchmarks in biopharma and biotechnology manufacturing.

Market Stats and Trends For AI In Biohealth Manufacturing

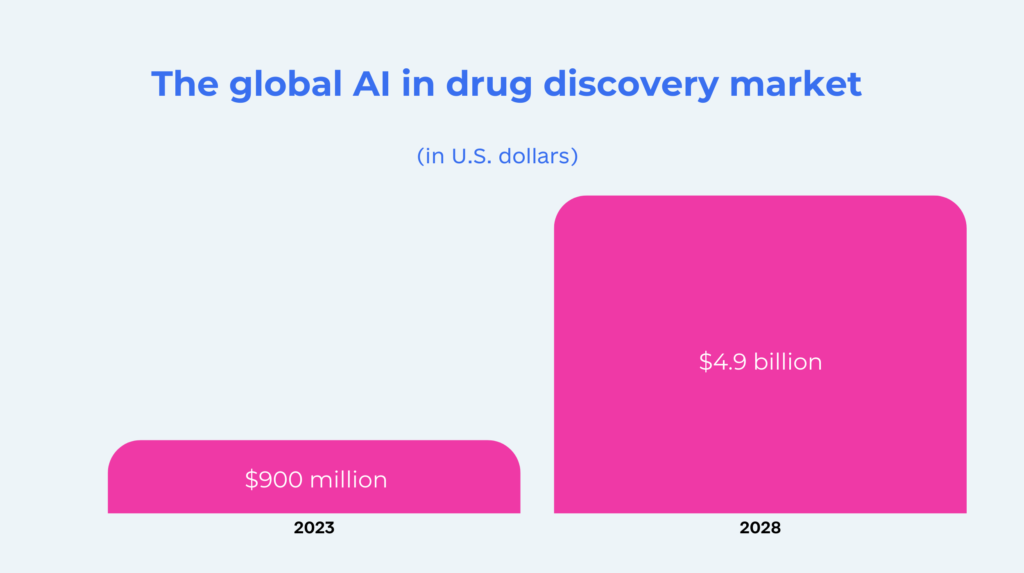

The global adoption of AI in biomanufacturing has been accelerating, driven by the growing need for efficiency and precision in biopharma manufacturing processes. According to a report by MarketsandMarkets, the global AI in drug discovery market was valued at $900 million in 2023 and is projected to reach $4.9 billion by 2028, growing at a compound annual growth rate (CAGR) of 40.2%. This rapid expansion underscores the pivotal role AI plays in advancing the industry.

Key regions leading this growth include North America and Europe. North America accounts for the largest share of the AI-driven biohealth manufacturing market, thanks to robust research infrastructure, significant government funding, and widespread adoption of AI in healthcare. Europe follows closely, with countries like Germany and the UK emphasizing innovation in AI and biotech to strengthen their pharmaceutical sectors.

Emerging Asian economies, such as China and India, are also making notable strides. China’s commitment to integrating AI into its biopharma industry has led to partnerships between biotech firms and AI startups. At the same time, India focuses on leveraging AI for cost-effective drug manufacturing and distribution. These regions are poised to reshape the global landscape by investing in cutting-edge AI technologies for biohealth applications.

Sector-Specific Trends

The convergence of AI in biomedical research and biopharma manufacturing has given rise to several transformative trends. One of the most impactful developments is personalized therapeutics, which tailors treatments to individual patient profiles. AI enables genetic, clinical, and environmental data analysis to create targeted therapies, significantly improving treatment outcomes. For instance, AI-driven platforms are used to identify biomarkers for specific cancers, paving the way for precision oncology.

Another emerging trend is the adoption of AI in optimizing biopharma production processes. AI-powered systems are being deployed to monitor bioreactors, predict production yields, and adjust parameters in real time, ensuring consistent quality. This approach has reduced waste and operational costs while enhancing scalability—a critical challenge in biomanufacturing.

Significant investments by leading firms highlight the growing importance of AI-driven platforms. In 2022, GlaxoSmithKline announced a $70 million partnership with AI startup Exscientia to apply machine learning to drug discovery, while Roche invested heavily in AI tools for genomic data analysis. These collaborations illustrate how AI and biotech are becoming increasingly interdependent in shaping the future of healthcare.

The rise of AI in biopharma manufacturing is not limited to production alone. AI’s ability to manage vast datasets and provide actionable insights is driving improvements across supply chains, regulatory compliance, and quality control. Predictive analytics tools help manufacturers anticipate bottlenecks, while AI systems ensure that products meet stringent safety and efficacy standards.

Overall, integrating AI across the biohealth manufacturing sector is setting new benchmarks for innovation, efficiency, and personalization in healthcare. These trends, supported by significant investment and adoption, signal a promising future for AI-driven advancements in the industry.

Challenges in Biohealth Manufacturing

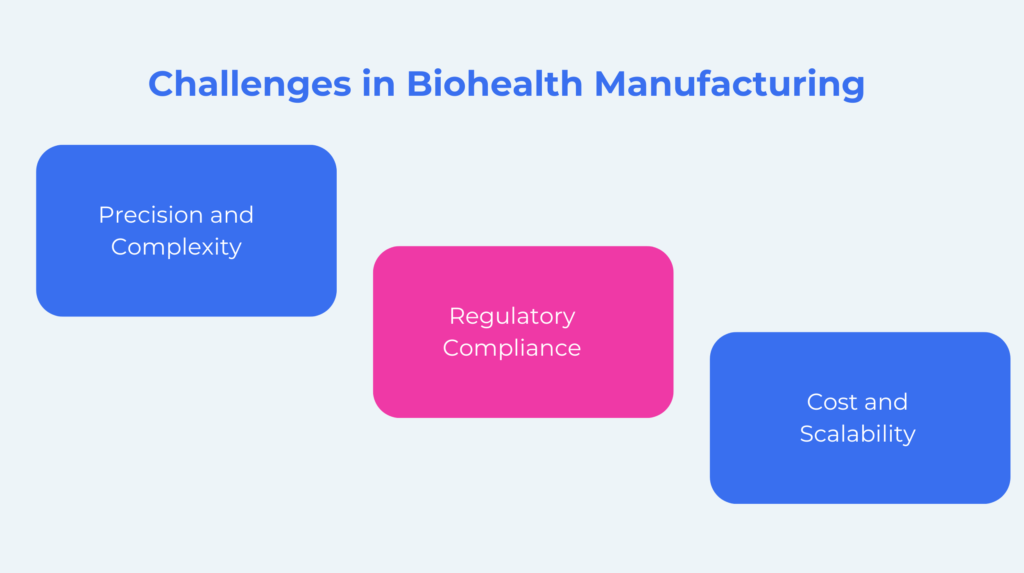

Precision and Complexity

The production of biologics in biotechnology manufacturing is inherently complex. Unlike chemical-based pharmaceuticals, biologics are derived from living cells, introducing variability in their behavior and output. Precision is critical at every step—from culturing cells and isolating proteins to the final formulation. Even minor deviations in conditions, such as temperature or nutrient supply, can significantly impact product consistency and efficacy.

For example, bioreactor conditions can vary slightly from batch to batch, making it challenging to maintain reproducibility. This has been a longstanding issue for biologics manufacturers, as noted in a Bioprocess Online article, which highlights the role of biohealth AI in optimizing production parameters to achieve consistency. AI tools analyze data in real time, identifying trends and deviations that might be missed by human operators.

However, implementing AI-based solutions is not without hurdles. These technologies require substantial investment in infrastructure, training, and algorithm validation to address precision challenges effectively.

Regulatory Compliance

Regulatory frameworks governing biohealth manufacturing are among the most stringent in the world. Organizations such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and global Good Manufacturing Practices (GMP) standards enforce rigorous requirements for product safety, efficacy, and quality.

Compliance involves detailed documentation, routine audits, and validation of every aspect of the manufacturing process. Manufacturers must demonstrate consistent production outcomes and swiftly address deviations to avoid penalties. A Riddle Compliance article explains that emerging technologies like AI in biomedical engineering can help meet these regulatory demands by automating documentation and improving traceability.

AI systems used in quality assurance must also be validated to prove their accuracy and reliability in decision-making. This often delays the adoption of AI tools as manufacturers navigate the complex interplay between technological innovation and compliance.

Cost and Scalability

Scaling biohealth manufacturing from a laboratory to a commercial level introduces significant financial and operational challenges. According to the Biotechnology Innovation Organization (BIO), the development and production of biologics can exceed $1 billion, with manufacturing costs comprising a substantial portion.

Bioreactors and other specialized equipment required for biologics are expensive and not easily scalable without impacting product quality. This creates barriers for smaller firms that lack the resources of large pharmaceutical companies. A Forbes article highlights how AI is being used to address these issues. Predictive modeling tools simulate various production scenarios, helping manufacturers find the most efficient and cost-effective scaling pathways.

In addition, AI in biomedical engineering can optimize resource allocation and monitor equipment performance in real time, reducing waste and preventing costly downtime. While these technologies offer long-term savings, their upfront costs and the need for skilled personnel can deter smaller companies from adopting them.

How AI Addresses These Challenges

Predictive Analytics and Process Optimization

AI’s predictive analytics capabilities are transforming biotechnology manufacturing by forecasting outcomes, optimizing processes, and reducing errors. These systems analyze historical and real-time data to identify patterns and predict potential challenges before they occur, allowing manufacturers to make proactive adjustments that ensure product consistency and quality.

For example, AI-driven digital twins—virtual replicas of physical processes—enable manufacturers to simulate and optimize bioprocesses virtually before implementation. This not only reduces errors but also enhances efficiency. According to a Bioprocess Online article, digital twins have been instrumental in minimizing risks and achieving greater consistency in biomanufacturing.

Additionally, AI enhances process analytical technologies (PAT), providing real-time data interpretation to make immediate quality control and automation decisions. As highlighted by GEN – Genetic Engineering & Biotechnology News, PAT systems powered by AI significantly improve operational efficiency and reduce manual intervention.

Quality Assurance with Real-Time Monitoring

Maintaining stringent quality standards is paramount in biohealth manufacturing. AI-driven systems play a critical role in biohealth AI applications, offering continuous real-time monitoring to identify defects and ensure compliance with regulatory standards.

AI tools analyze production data at every stage, identifying anomalies that might indicate quality issues. This allows for immediate corrective actions, preventing defective products from reaching the market. For instance, an AI-enabled quality control system highlighted in a Pharmaceutical Manufacturing article showcases how integrating AI into quality assurance processes reduces errors and improves batch consistency.

Moreover, digital twins also support real-time quality monitoring by creating dynamic digital replicas of production processes. These twins offer intelligent closed-loop control, ensuring that batches meet quality specifications during every production cycle. According to Nature Biotechnology, this approach has been vital in scaling precision biopharma manufacturing.

Data Integration and Decision Support

The complexity of biohealth manufacturing generates vast datasets from multiple sources, including bioreactors, sensors, and quality control tests. AI excels at integrating and synthesizing these datasets, offering actionable insights that improve decision-making.

By analyzing data from disparate sources, AI systems uncover trends and correlations that traditional methods might overlook. These insights help optimize resource allocation, improve process workflows, and maintain consistent quality standards. A report from McKinsey highlights how AI in biomedical engineering has streamlined data management and enhanced decision-making across various stages of production.

One example of this is AI-powered predictive models used to optimize fermentation and cell culture processes. These models combine historical and real-time data to suggest adjustments that maximize yield and maintain product quality. A case study from MIT Technology Review illustrates how AI-driven decision support systems have reduced production costs and improved scalability.

Additionally, AI systems improve regulatory compliance by automating data logging and traceability. Tools like natural language processing (NLP) analyze documentation for discrepancies, ensuring adherence to standards like FDA, EMA, and GMP.

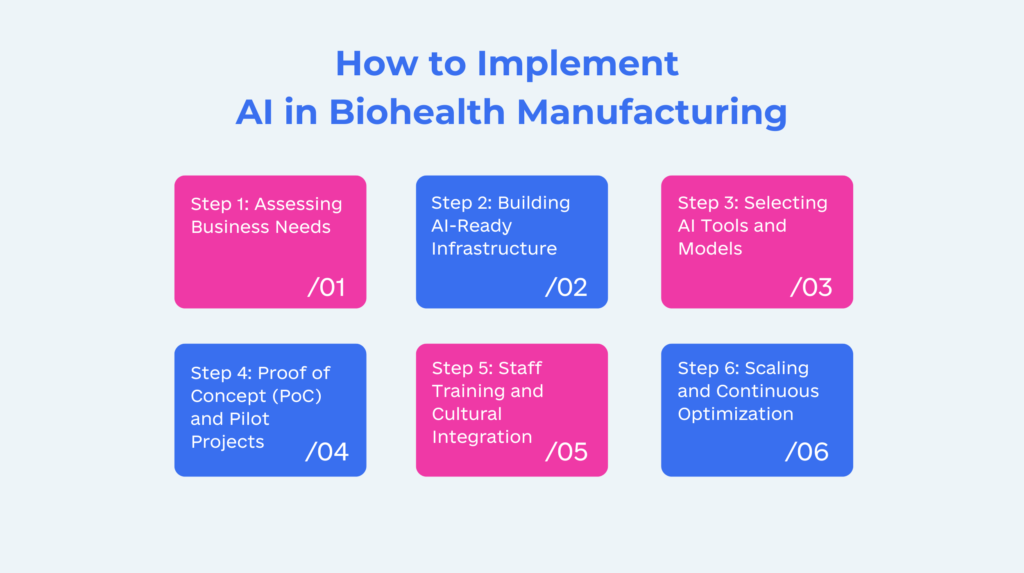

How to Implement AI in Biohealth Manufacturing

The integration of AI in biomanufacturing offers tremendous potential to optimize processes, enhance quality, and accelerate production timelines. However, implementing AI effectively requires a structured and methodical approach. This section outlines six essential steps to ensure the successful adoption of AI in biomedical engineering and biohealth applications.

Step 1: Assessing Business Needs

The first step in implementing AI is identifying pain points in the current manufacturing process and setting clear objectives. Start by evaluating your operations to determine where AI can provide the most value. Common challenges include variability in production outcomes, inefficiencies in resource utilization, and compliance with regulatory standards.

For example, if inconsistencies in cell culture growth are leading to production delays, AI in biomedicine can help optimize conditions by analyzing historical and real-time data. A case study published by Bioprocess Online highlights how predictive AI models reduced variability in biologics production by 25%.

To establish actionable goals, align AI objectives with broader business priorities. This may involve increasing production yield, reducing costs, or achieving faster regulatory compliance. Clearly defined metrics for success will guide the development and deployment of AI systems, ensuring alignment with organizational goals.

Step 2: Building AI-Ready Infrastructure

Implementing AI requires robust infrastructure to handle large datasets and ensure compatibility with existing systems. Key components of AI-ready infrastructure include:

- Data Pipelines: Set up systems to collect, store, and preprocess data from sensors, monitoring equipment, and other production sources. Ensuring data integrity and accessibility is critical for AI systems to generate reliable insights.

- Cloud Storage and Computing: Invest in scalable cloud solutions to support the processing and analysis of vast datasets. According to McKinsey, cloud-based platforms reduce infrastructure costs and enable seamless integration of AI tools.

- Compliance Frameworks: Develop infrastructure that adheres to regulatory standards such as FDA, EMA, and GMP. This includes audit trails, data security protocols, and systems for maintaining traceability.

- Interoperability: Ensure that AI platforms are compatible with legacy systems to avoid disruptions during implementation.

Building an AI-ready infrastructure also involves preparing for future advancements. As technologies like AI in biomedical engineering evolve, your systems should be flexible enough to accommodate updates and integrations.

Step 3: Selecting AI Tools and Models

Choosing the right AI tools and algorithms is essential for addressing specific challenges in biohealth manufacturing. Consider the following factors when selecting platforms:

- Purpose: Determine whether the tool is designed for predictive analytics, real-time monitoring, or data integration. For instance, AI tools like TensorFlow and PyTorch are widely used to develop custom AI models in biomanufacturing.

- Customization: Evaluate whether the AI tool can be tailored to the unique requirements of your manufacturing processes. A report from GEN – Genetic Engineering & Biotechnology News discusses how customizable AI models enhance precision and adaptability.

- Scalability: Select tools that can grow with your operations, especially if you plan to scale production in the future.

- Vendor Support: Partner with reputable AI vendors that provide implementation support, training, and updates.

Collaborate with AI specialists to identify algorithms and platforms best suited to your needs. For example, deep learning models are highly effective for image analysis and anomaly detection, while machine learning algorithms excel at predictive analytics.

Step 4: Proof of Concept (PoC) and Pilot Projects

Before deploying AI across your manufacturing operations, validate its impact through a Proof of Concept (PoC) or pilot project. This step involves testing AI tools in a controlled environment to assess their feasibility and effectiveness.

Strategies for a Successful PoC:

- Define Scope: Focus on a specific pain point, such as optimizing a single bioreactor or improving quality assurance for one product line.

- Set Benchmarks: Establish measurable KPIs, such as yield improvement, error reduction, or time savings.

- Collaborate: Involve cross-functional teams, including production managers, data scientists, and quality assurance personnel, to ensure comprehensive evaluation.

A Nature Biotechnology case study demonstrates how a biopharma company used AI-driven digital twins in a pilot project to reduce production errors by 30%, validating its use for broader implementation.

Step 5: Staff Training and Cultural Integration

The success of AI implementation depends on workforce readiness and organizational culture. Employees must understand the value of AI tools and feel confident using them.

Training Strategies:

- AI Literacy: Educate staff on the basics of AI, including its capabilities and limitations.

- Hands-On Training: Provide practical experience with AI tools to build confidence and competence.

- Role-Based Training: Tailor programs to specific roles, such as data entry, quality assurance, or process optimization.

Cultural integration involves fostering an environment of innovation and collaboration. Encourage employees to embrace AI as a tool that complements their expertise rather than replacing it. Highlight success stories and early wins to build trust and enthusiasm across teams.

Step 6: Scaling and Continuous Optimization

Once AI solutions have been validated and integrated, the next step is scaling their implementation across multiple processes and facilities.

Best Practices for Scaling AI:

- Iterative Deployment: Roll out AI tools in phases to ensure a smooth transition and address challenges as they arise.

- Monitoring and Feedback: Continuously evaluate the performance of AI systems and gather feedback from users to make necessary adjustments.

- Model Refinement: Regularly update AI models with new data to maintain accuracy and relevance.

A report from Pharmaceutical Technology emphasizes the importance of ongoing optimization. As production volumes grow, AI systems must adapt to new variables and demands, ensuring sustained efficiency and quality.

Case Studies and Use Cases of AI

Artificial Intelligence (AI) has demonstrated significant potential across various aspects of biohealth manufacturing, from improving operational efficiency to accelerating research. This section highlights real-world examples and innovations in AI in biotechnology, AI in biomedical research, and AI and biotech collaborations, showcasing its transformative impact on the industry.

AI in Biopharma Manufacturing

AI is driving operational efficiency and compliance in biopharma manufacturing, ensuring products meet stringent quality and safety standards.

Case Study: Pfizer’s Partnership with IBM Watson

Pfizer partnered with IBM Watson Health to accelerate its immuno-oncology research, leveraging IBM’s cognitive computing capabilities to analyze extensive datasets and identify promising therapeutic candidates. The use of AI significantly reduced research timelines while maintaining compliance with regulatory guidelines.

A detailed announcement of this partnership is available in an IBM Newsroom article. This collaboration allowed Pfizer’s researchers to process and interpret complex data more efficiently, facilitating the identification of novel drug targets and combination therapies.

This example highlights the power of AI in biomedicine, showcasing how cognitive computing can enhance research and development in the pharmaceutical industry.

Case Study: Novartis Using AI for Process Optimization

Novartis has embraced AI to optimize its manufacturing processes, focusing on leveraging machine learning to analyze production data, identify inefficiencies, and enhance workflows. By integrating AI tools, the company has successfully streamlined operations, reduced costs, and improved overall yield in its production facilities.

A detailed overview of Novartis’ broader digital transformation initiatives, including their use of AI in biopharma manufacturing, is provided by a case study from Accenture. This highlights their efforts to use data-led strategies for reimagining manufacturing processes and achieving operational excellence.

For insights into broader applications of machine learning in process efficiency, McKinsey’s report on operationalizing machine learning in processes offers valuable strategies that align with Novartis’ approach to AI-driven process optimization.

Compliance Enhancement with AI

AI tools like natural language processing (NLP) are helping companies streamline regulatory compliance by automating documentation review and tracking changes in global regulations. This approach ensures faster submissions and reduced human error.

AI in Biotechnology Manufacturing

The integration of AI in biotechnology manufacturing has led to innovations in sustainability and precision bioprocessing.

Case Study: Amgen’s AI-Driven Bioprocessing

Amgen has been actively integrating AI systems to enhance precision and sustainability in its bioprocessing operations. By utilizing AI to monitor bioreactors in real-time, Amgen optimizes cell culture conditions, thereby reducing resource consumption and minimizing environmental impact. This approach aligns with their commitment to innovative and sustainable manufacturing practices, as detailed in their Environmental Sustainability initiatives.

For a comprehensive overview of Amgen’s sustainability efforts and the role of AI in their operations, you can refer to their 2023 Environmental, Social & Governance Report.

Precision Bioprocessing

AI-driven digital twins—virtual replicas of manufacturing processes—are revolutionizing precision bioprocessing in the biopharmaceutical industry. These sophisticated models simulate production scenarios, enabling companies to predict bottlenecks and enhance throughput without compromising quality.

A comprehensive overview of how digital twins and AI are reshaping biopharmaceutical manufacturing is provided in a GEN article. This resource delves into the integration of digital twins with AI to improve process control and monitoring, expediting regulatory approval of drug products.

Additionally, insights into addressing AI bottlenecks in bioprocessing are discussed in another GEN article. This piece explores challenges and solutions related to AI implementation in bioprocessing, emphasizing the importance of interpretability and data integration.

Sustainability Innovations

AI also facilitates more sustainable production by optimizing energy and water usage during manufacturing. For instance, AI-powered sensors monitor energy consumption in real-time, allowing manufacturers to minimize waste while maintaining efficiency. A Nature Biotechnology article discusses the role of AI in driving sustainable biomanufacturing practices.

These case studies illustrate how AI is transforming biopharma manufacturing, biotechnology manufacturing. From enhancing precision and sustainability to accelerating therapy development, AI is setting new benchmarks for efficiency and innovation in the biohealth industry. By adopting AI-driven solutions, companies can navigate challenges, seize opportunities, and drive advancements that improve patient outcomes and global health.

How Achievion Solutions Can Help

Achievion Solutions has established itself as a leader in developing tailored biohealth AI solutions, empowering healthcare organizations to overcome challenges in manufacturing, process optimization, and patient care. By leveraging expertise in AI biomedical engineering and AI in biomanufacturing, Achievion delivers transformative systems that enhance efficiency, precision, and scalability.

Custom AI Solutions for Biohealth Manufacturing

Achievion specializes in creating AI-powered models tailored for biohealth manufacturing, addressing the industry’s unique demands. These solutions integrate predictive analytics, real-time monitoring, and data integration to streamline operations and ensure consistent quality.

For instance, in the realm of AI in biomanufacturing, Achievion’s models optimize production conditions by analyzing data from bioreactors. These tools reduce variability and improve product yield by predicting optimal parameters for cell cultures. Furthermore, Achievion’s expertise in AI biomedical engineering ensures that the solutions meet stringent compliance standards while maintaining operational efficiency.

Whether addressing challenges in biopharmaceutical production or automating quality control, Achievion’s biohealth AI models are designed to deliver measurable results.

Comprehensive Implementation Support

Achievion provides end-to-end support for implementing AI systems in healthcare and manufacturing environments. Their comprehensive services cover every project lifecycle stage, ensuring seamless deployment and long-term scalability.

- Initial Deployment:

Achievion begins by assessing organizational needs and identifying pain points in the current manufacturing or healthcare processes. This phase involves creating a customized implementation plan tailored to specific operational goals. - System Integration:

To ensure smooth adoption, Achievion integrates AI tools with existing infrastructure, prioritizing compatibility and minimizing disruptions. This step includes setting up data pipelines, cloud infrastructure, and compliance frameworks aligned with industry standards. - Scalability and Optimization:

Achievion’s solutions are designed for scalability, enabling organizations to expand AI applications across multiple facilities or product lines. Continuous monitoring and refinement ensure that AI systems remain effective and adaptive to changing needs. - Regulatory Compliance:

With expertise in global regulatory frameworks like FDA and GMP, Achievion helps organizations navigate compliance challenges, ensuring that AI solutions meet all necessary standards.

Proven Success in AI Projects

Achievion’s track record includes delivering innovative AI solutions that drive measurable improvements in healthcare and biohealth manufacturing. Below are examples of their successful projects:

1. AI-Powered Heart Monitoring Software for Medical Devices

Achievion developed an advanced heart monitoring system that utilizes AI algorithms to detect irregular cardiac rhythms in real-time. This software has improved the accuracy of diagnostics and enhanced patient care, offering a reliable tool for medical professionals. By integrating predictive analytics, the system reduces the risk of undetected abnormalities, making it a valuable addition to cardiac care technologies.

AI-Powered Heart Monitoring Software for Medical Devices

2. Patient Care Process Optimization with AI

Achievion implemented an AI-driven solution to optimize patient care processes in a project aimed at streamlining hospital operations. The system analyzed workflow inefficiencies, provided actionable insights, and enabled real-time adjustments. As a result, hospitals experienced reduced wait times, improved resource allocation, and enhanced patient satisfaction.

Patient Care Process Optimization with AI

3. Drug Effectiveness Prediction Software

Achievion’s AI model for predicting drug effectiveness achieved a 46% reduction in treatment-related side effects, significantly improving patient outcomes. The software enables healthcare providers to tailor treatments for better safety and efficacy by analyzing patient data and identifying potential adverse reactions. This project highlights Achievion’s expertise in applying AI to improve decision-making and patient care.

Drug Effectiveness Prediction Software

Achievion Solutions stands at the forefront of AI innovation, offering tailored solutions that empower organizations to harness the full potential of AI. With expertise in AI biomedical engineering and a proven track record of delivering impactful projects, Achievion provides end-to-end support, from strategy development to system integration and optimization.

Whether you want to enhance your biomanufacturing processes or streamline healthcare operations, Achievion’s customized AI solutions are designed to meet your unique needs. Explore Achievion’s portfolio of successful projects and take the first step toward transforming your operations.

Partner with Achievion Solutions today and revolutionize the future of biohealth manufacturing. Contact us now to begin your AI journey.